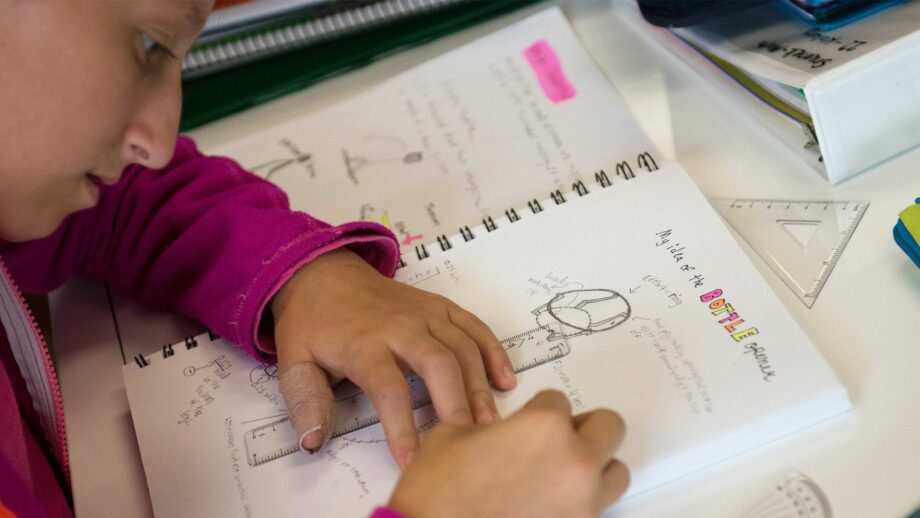

Sketching

Sketching in a free flowing manner is a great way to transform ideas into designs. Check out the video below from the Product Designer Maker YouTube channel, where Chris shows us how to build ideas on paper, rather than to simply record ideas which have already formed in our heads. Don't forget to check out the other amazing videos on his YouTube channel!